Description

As a Manufacturing Manager, Will is responsible for overseeing the entire manufacturing process, from the acquisition of raw materials to the production and delivery of finished products. He coordinates with various departments, such as engineering, quality control, and logistics, to ensure that all manufacturing operations run smoothly and efficiently. Will is also responsible for managing the budget, ensuring compliance with safety regulations, and implementing strategies to optimize production and reduce costs.

Will’s KPIs as Manufacturing Manager:

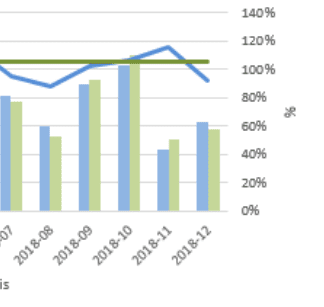

Key Performance Indicators (KPIs) for a Manufacturing Manager may vary depending on the specific goals and objectives of the organization, but here are some common KPIs that can be used:

- Production output: This KPI measures the total amount of goods produced within a given period, such as a day, week, or month. It can be measured in units or dollars.

- Quality control: This KPI measures the percentage of goods produced that meet the company’s quality standards. It can be measured by the number of defects found per unit of output or by customer satisfaction ratings.

- Cost reduction: This KPI measures the percentage of cost savings achieved through process improvement, waste reduction, or other efficiency measures.

- On-time delivery: This KPI measures the percentage of orders delivered on or before the scheduled delivery date. It can be measured by the number of late deliveries or customer complaints related to delivery times.

- Equipment utilization: This KPI measures the percentage of time manufacturing equipment is in use. It can be measured by the number of hours a machine is in operation compared to the number of hours it is available.

- Workforce productivity: This KPI measures the efficiency of the workforce, such as the number of units produced per employee or the number of hours worked per unit produced.

- Inventory management: This KPI measures the percentage of inventory turnover and the number of days inventory is held. It can be measured by the number of inventory turns per year or the average time inventory is held.

- Safety: This KPI measures the number of accidents or injuries that occur in the manufacturing process. It can be measured by the number of incidents per thousand hours worked or by the number of lost workdays due to injury.

By tracking these KPIs, a Manufacturing Manager can monitor the performance of the manufacturing process, identify areas for improvement, and make data-driven decisions to increase efficiency, reduce costs, and improve quality.

Will’s SIPOC as Manufacturing Manager:

- Supplier: Raw Material Suppliers, Equipment Suppliers, Maintenance Services

- Inputs: Raw Materials, Production Schedule, Quality Standards, Maintenance Requests

- Process: Manufacturing Process (Includes Quality Control and Maintenance)

- Outputs: Finished Goods, Quality Control Reports, Maintenance Reports

- Customers: Distributors, Retailers, End-users

Let’s break this down further:

Supplier: Raw Material Suppliers, Equipment Suppliers, Maintenance Services

As a Manufacturing Manager, the first step is to identify the suppliers who provide the raw materials required for the manufacturing process. These raw materials can be anything from steel, plastic, rubber, etc. The equipment suppliers who provide the machinery used in the manufacturing process are also important. Additionally, maintenance services may be required for the equipment, so the manager must also identify and manage suppliers who provide maintenance services.

Inputs: Raw Materials, Production Schedule, Quality Standards, Maintenance Requests

The Manufacturing Manager must ensure that raw materials are procured in a timely manner and in the right quantity. The production schedule is important, as it dictates how much of each product needs to be manufactured and when. Quality standards are also essential, as the finished goods must meet the required quality standards to be sold to customers. Finally, the manager must also consider maintenance requests to ensure that the equipment is functioning optimally and does not cause any delays in the production process.

Process: Manufacturing Process (Includes Quality Control and Maintenance)

The Manufacturing Manager is responsible for managing the entire manufacturing process, which includes raw material handling, production, quality control, and maintenance. The manager must ensure that the manufacturing process is efficient, cost-effective, and produces high-quality finished goods. Regular checks must be conducted to ensure that the process is functioning as intended, and any necessary improvements or changes must be made to optimize the process.

Outputs: Finished Goods, Quality Control Reports, Maintenance Reports

The Manufacturing Manager is responsible for ensuring that the finished goods are of high quality, meet the required specifications, and are ready for distribution to customers. Quality control reports must be generated to ensure that the finished goods meet the required quality standards. Additionally, maintenance reports must be generated to ensure that the equipment is functioning optimally and does not cause any delays in the production process.

Customers: Distributors, Retailers, End-users

The Manufacturing Manager is responsible for ensuring that the finished goods are distributed to the appropriate customers, which include distributors, retailers, and end-users. The manager must ensure that the finished goods are delivered on time, are of the required quality, and meet the customer’s expectations. Customer feedback should also be taken into consideration to improve the manufacturing process and the finished product.

Role of data

As a Manufacturing Manager, you oversee the production process of goods from raw materials to finished products. In today’s digital age, data plays an increasingly important role in optimizing manufacturing operations and improving overall efficiency.

Data can provide valuable insights into the performance of production processes and the overall health of your manufacturing operations. With the help of data, you can identify areas of inefficiency and waste, as well as opportunities for improvement. This information can help you make informed decisions about how to optimize production, reduce costs, and improve quality.

One of the key benefits of data in manufacturing is the ability to monitor production in real-time. Real-time monitoring allows you to track the performance of machines and equipment, identify any issues or bottlenecks in the production process, and take corrective action before it impacts production.

Another important use of data in manufacturing is predictive maintenance. By collecting data on equipment performance over time, you can identify patterns and predict when maintenance will be required. This allows you to schedule maintenance proactively, reducing downtime and minimizing the risk of equipment failure.

Data can also be used to improve supply chain management. By collecting data on suppliers, inventory levels, and production schedules, you can optimize the flow of materials through the supply chain and minimize the risk of stockouts or overstocks.

Finally, data can be used to improve quality control. By collecting data on product defects, you can identify patterns and take corrective action to reduce the number of defects in future production runs. This can help improve customer satisfaction and reduce costs associated with returns and rework.

Overall, data plays a critical role in the success of manufacturing operations. By using data to monitor production, optimize processes, and improve quality, you can increase efficiency, reduce costs, and deliver high-quality products to your customers. As a Manufacturing Manager, it’s important to embrace the role of data in your operations and leverage it to drive continuous improvement.