Description

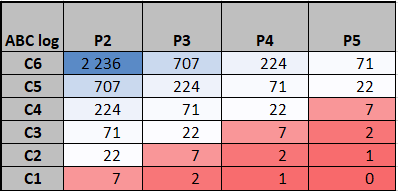

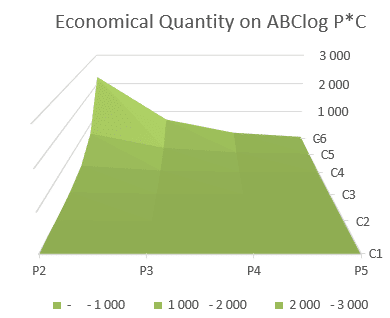

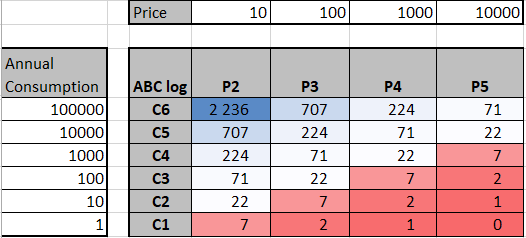

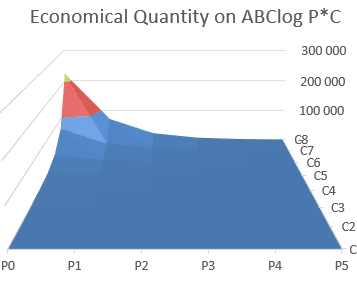

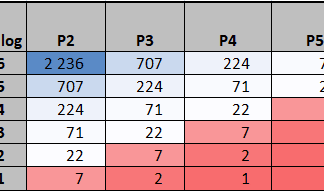

Use Wilson formula to calculate Economical Quantity on ABC log Classes Price * Consumption

https://www.inventorybigdata.com/wp-content/uploads/presentations/Economical_Qty_on_ABClog.xlsx

EOQ stands for Economic Order Quantity. It is the quantity ordered from the supplier to allow replenishment while minimizing the total cost of the stock.

The stock level reaches the order point when the order is triggered.

The EOQ is calculated with the aim of minimizing a synergy of costs such as purchasing cost, storage cost. Optimizing the order quantity is additional to optimizing the safety stock.

To do this, the Wilson formula is used. This is a stock optimization formula. In order to be able to calculate the economic order quantity in your company.

What does REOQ mean?

REOQ stands for “Reorder Quantity” and it is a term used in inventory management to refer to the amount of inventory that should be ordered when the inventory level reaches a certain point. The reorder quantity is typically calculated based on the expected demand for the product, the lead time for reordering, and the holding costs associated with maintaining the inventory. The goal of calculating the reorder quantity is to find the optimal balance between keeping enough inventory on hand to meet demand, while also minimizing excess inventory and related holding costs.

In inventory management, the reorder point is the inventory level at which a new order should be placed. The reorder quantity is the amount of inventory that should be ordered when the reorder point is reached. Together, the reorder point and the reorder quantity help to ensure that the inventory is maintained at an optimal level, without running out of stock or accumulating excess inventory.

Optimize Inventory Management with the Wilson Formula and EOQ

Welcome to the optimized realm of inventory management! Navigate through our guide at InventoryBigData.com and ABCLog.com, showcasing the Wilson Formula’s prowess in calculating Economical Quantity based on ABC Log Classes Price * Consumption.

Understanding EOQ – Anchoring Efficient Replenishment:

Economic Order Quantity (EOQ) is the linchpin of efficient replenishment. It ensures optimal supplier orders, minimizing overall stock costs. When stock levels hit the order point, replenishment commences.

EOQ orchestrates cost harmony, aligning purchasing and storage costs for optimal order quantities. It seamlessly complements safety stock management, a bedrock of robust inventory control.

Enter the Wilson Formula, a dynamic tool fine-tuning order quantities for cost efficiency and inventory enhancement. Explore how it revolutionizes your inventory strategies, fortifying your company’s financial standing.

Deciphering REOQ – Crafting Balanced Inventory:

Discover Reorder Quantity (REOQ), a pivotal concept in inventory management. It designates inventory quantity upon hitting specific stock levels. Calculated based on demand projection, lead times, and holding costs, REOQ strives to balance inventory and minimize excess expenses.

Complementing REOQ is the Reorder Point, signaling new orders at defined inventory levels. Mastering both elements ensures equilibrium between meeting demand and curbing excess inventory costs.

Embark on this illuminating journey through effective inventory management. Harness the synergy of the Wilson Formula, EOQ, and REOQ, reshaping your inventory processes for cost-effectiveness and optimal stock levels. Dive in now and unlock successful inventory management at InventoryBigData.com and ABCLog.com.