Description

Navigating the complex world of inventory management is a daunting task that supply chain experts confront daily. From grappling with outdated spreadsheet methods to balancing between excess stock and urgent, costly reorders, mismanaging inventory can have significant repercussions. However, modern supply chain tools, with their cloud-based infrastructure and advanced algorithms, are making these challenges easier to address. Let’s delve into the four core components that these tools often present: Connect, Forecast, Optimise, and Order.

1. Connect: Integrating with Enterprise Systems

Integration is the foundation of modern supply chain management. With disparate systems and platforms running in an enterprise, a tool that can seamlessly link with an Enterprise Resource Planning (ERP) or an existing business system becomes invaluable. The ‘Connect’ feature of advanced tools facilitates this, ensuring quick, hassle-free integrations and an immediate start.

2. Forecast: Advanced Demand Prediction

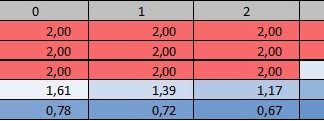

Traditional forecasting methods, reliant on spreadsheets and manual calculations, are riddled with potential inaccuracies. Modern tools employ state-of-the-art algorithms that can offer accurate demand forecasting. They take into account various factors, from seasonality and trending demands to promotional activities, enabling businesses to move beyond manual errors and into the realm of precise projections.

3. Optimise: Balancing Stock Levels

Holding too much stock can tie up valuable capital, while running out can lead to lost sales. Finding the right balance is pivotal. The ‘Optimise’ function of contemporary supply chain tools is designed to address this. It can automatically calculate necessary stock levels, determining reorder points, optimal order quantities, and safety stock levels. This automation ensures businesses always have just the right amount of stock.

4. Order: Streamlining Purchasing Decisions

The act of ordering inventory should be data-driven, not guesswork. The ‘Order’ component in these tools offers this exact precision. With functionalities that auto-calculate order quantities and align supplier orders, businesses can make intelligent purchasing decisions. Some tools even allow for maximizing shipping efficiencies by offering functionalities to optimize shipping container space. Ultimately, businesses can review and confirm order suggestions, ensuring they’re always making the best decisions.

Conclusion

Inventory management is not merely about maintaining stock; it’s a strategic operation that, when done right, can significantly impact a business’s bottom line. The four-pillared approach, as showcased in contemporary supply chain tools, reflects this philosophy. For businesses looking to revamp their inventory management processes, embracing these advanced tools can pave the way for greater efficiency, precision, and profitability.