Description

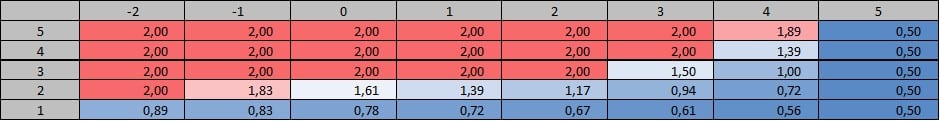

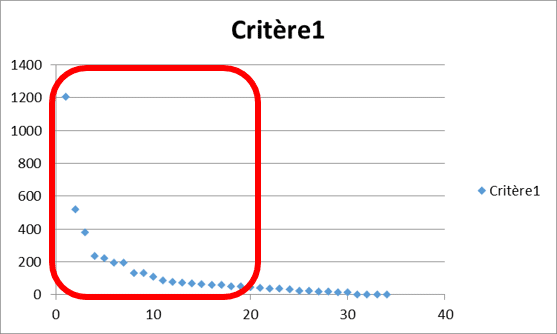

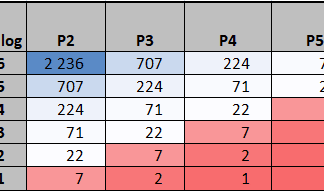

Use a modification parameter to the wilson formula according to ABC classes Price * consumption.

Wilson formula has a flat bootom curve. Economical quantity can be adjusted to make more quick win on inventory values.

The reorder quantity

The reorder quantity, also known as the reorder level or reorder point, is a measure used in inventory management to determine when it is necessary to restock a particular item. The reorder quantity is calculated based on the rate of consumption or usage of the item, the lead time required to receive a new shipment, and the desired level of safety stock.

In general, the reorder quantity is the point at which the inventory of a particular item falls below a certain level, and a new order needs to be placed to avoid running out of stock. By setting a reorder quantity and regularly monitoring inventory levels, businesses can ensure that they have a sufficient supply of the items they need to meet customer demand and avoid stock-outs.

The reorder quantity can be calculated using a variety of methods, including the economic order quantity (EOQ) model, which is based on the cost of placing an order and the cost of carrying inventory. Other factors that may be taken into consideration when determining the reorder quantity include the availability of the item, the cost of the item, and the level of customer demand.

Why is the REOQ so important for a manufacturer?

The economic order quantity (EOQ) model is a tool used by manufacturers to determine the optimal order quantity for a product, given certain variables such as the demand for the product, the cost of placing an order, and the cost of holding inventory. The goal of the EOQ model is to minimize the total cost of inventory, which includes the cost of placing orders and the cost of holding inventory.

By minimizing these costs, the EOQ model can help manufacturers improve their financial performance. For example, if a manufacturer is able to reduce the number of orders it places and the amount of inventory it holds, it can save money on purchasing and storage costs. This can lead to lower overall costs and higher profits for the manufacturer.

Additionally, using the EOQ model can help manufacturers ensure that they have the right amount of inventory on hand to meet customer demand, which can help improve customer satisfaction and potentially lead to increased sales and revenue.

Overall, the EOQ model is an important tool that can help manufacturers optimize their inventory management and improve their financial performance.