Description

Effective Management of SLow-moving and OBsolete inventory (SLOB): A Vital Pillar of Inventory Control

In the dynamic landscape of inventory control, your warehouse may already play host to an array of slow-moving and obsolete inventory (SLOB). As these products continue to languish in your stock, their presence poses a looming threat to your business’s vitality. In the forthcoming discourse, you shall elucidate a comprehensive strategy to vigilantly monitor and proficiently manage your SLOB, ensuring the enduring profitability of your supply chain and the sustainability of your business.

The term ‘slow-moving’ is aptly employed to delineate goods or products characterized by sluggish turnover rates within a company. On the other hand, ‘obsolete’ pertains to goods or products that have plummeted into obscurity, either due to a lack of demand or the cessation of their production by the supplier.

Slow-moving inventory represents one of the more challenging aspects of inventory management, potentially tying up valuable resources and capital that could otherwise be deployed more effectively. Identifying and managing these items is crucial for maintaining an efficient and profitable supply chain. In this article, we explore the inherent challenges of managing slow-moving inventory and propose strategic approaches to mitigate these obstacles, thereby enhancing overall business operations.

Table of Contents

- Securing a Profitable Supply Chain

- Unveiling the Nuances of Slow-Moving and Obsolete Inventory (SLOB)

- Navigating the Realm of Obsolete Stock

- Proficiently Managing Slow-Moving Stock

- Embracing the SLOB KPI in Your Business

- Crunching the Numbers: Calculating Obsolete Inventory

- Quantifying Slow-Moving Inventory

Securing a Profitable Supply Chain

Should you aspire to fortify the profitability of your supply chain and, by extension, your entire business, your focus must converge upon a trinity of foundational pillars: service, costs, and inventory liquidity. Today, however, our scrutiny will be particularly acute, zeroing in on the realm of SLOB—slow-moving inventory and its antiquated counterpart, obsolete stock.

To start, managing Slow-Moving and Obsolete (SLOB) inventory effectively requires a proactive and strategic approach that addresses both the symptoms and the root causes of inventory stagnation. The first step in this process is precise identification and regular review of inventory status. This involves segmenting inventory to determine which items are slow-moving due to cyclical demand versus those that are truly obsolete. Advanced predictive analytics and inventory forecasting tools can significantly aid in this task, enabling businesses to better predict demand patterns and adjust inventory levels accordingly. These tools also help in identifying potential slow-moving items before they become a financial burden.

Next, an effective strategy for minimizing SLOB inventory is the implementation of a robust inventory optimization system. This includes revising procurement practices, enhancing the accuracy of demand forecasting, and improving the agility of the supply chain. For instance, adopting a Just-In-Time (JIT) inventory system can reduce inventory holding costs and increase inventory turnover rates by aligning inventory deliveries more closely with production schedules. Additionally, renegotiating supplier contracts to allow for more flexible order quantities and return policies can also alleviate the risk of accumulating excess stock. Moreover, regular collaboration and communication with suppliers, customers, and internal stakeholders are crucial to synchronize supply chain operations and optimize inventory flow.

Furthermore, for inventory that inevitably becomes obsolete or remains slow-moving, creative and effective liquidation strategies must be employed. This can involve discounting products for quick sale, bundling them with more popular items, or selling them to liquidators or through alternative markets such as outlet stores or online marketplaces. Recycling or repurposing parts of the inventory for other products or uses within the company can also be a cost-effective way of handling SLOB inventory. These strategies not only help in recovering value from slow-moving stocks but also free up valuable warehouse space and resources, thereby enhancing overall supply chain efficiency and profitability.

Unveiling the Nuances of Slow-Moving and Obsolete Inventory (SLOB)

Let us embark on our exploration by unraveling a fundamental question: what demarcates the demesne of slow-moving inventory from the realm of obsolete stock?

Slow-moving inventory consists of items that have lower sales velocity and therefore remain in stock longer than other products. These items can vary widely depending on the industry, market demand, and seasonal factors. The first challenge in managing slow-moving inventory is accurately identifying which products fall into this category. This requires a robust system to track and analyze sales over time, juxtaposed with inventory levels, to pinpoint products that consistently underperform.

Navigating the Realm of Obsolete Stock

Obsolete stock casts its shadow over products that have fallen into disuse, expired, or become relics of bygone eras. These are the items that must either be disposed of, sold at steep discounts, or even given away, for they have journeyed beyond the realms of saleability. The impact of obsolete inventory on a company’s financial health is profound, as it inexorably forfeits 100% or more of its value, factoring in the costs associated with its disposal.

The primary challenge posed by slow-moving inventory is the financial strain it places on a business. Capital tied up in unsold goods is capital not available for reinvestment in other, potentially more profitable, areas. Moreover, slow-moving items occupy valuable warehouse space, contribute to higher storage costs, and can become obsolete over time, leading to write-offs that impact the financial health of the company.

Proficiently Managing Slow-Moving Stock

Slow-moving inventory, colloquially known as excess stock, aged inventory, or residual inventory, represents products that, while not outdated or hailing from yesteryears, loiter in surplus. The presence of excess inventory begets additional costs, whether through storage expenses or the impending necessity to clear the surplus to accommodate new collections.

Excess inventory, however, does not necessarily equate to obsolescence.

To bring clarity to this labyrinthine inventory landscape and bid adieu to both slow-moving and obsolete inventory, a fundamental tool at your disposal is the calculation of inventory turnover. You’ll find invaluable insights into this subject in my articles on ‘Calculating Economic Order Quantity (EOQ)’ and ‘Formula and Calculation of Safety Stock: 6 Best Methods.’

Effective management of slow-moving stock heavily depends on accurate inventory data and sophisticated forecasting techniques. A common challenge is the lack of precise inventory tracking systems that can update in real-time and provide actionable insights. Without accurate data, forecasting becomes guesswork, complicating efforts to align inventory levels with market demand. Advanced predictive analytics can help address this by providing more accurate demand forecasts and identifying potential slow movers before they accumulate.

Embracing the SLOB KPI in Your Business

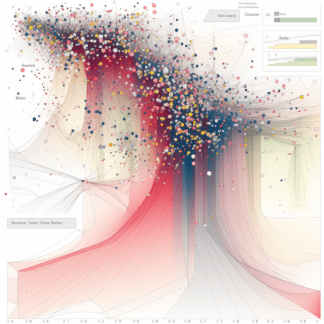

Your journey to effciently manage SLOB commences with the immediate download of my free Excel template, meticulously designed to facilitate the expedited calculation of the SLOB Key Performance Indicator (KPI).

Another significant challenge is the rigidity in procurement and supply chain operations. Traditional ordering systems might create scenarios where companies over-purchase items due to bulk-buying incentives or minimum order quantities imposed by suppliers. This practice often exacerbates the problem of slow-moving inventory. Flexible procurement strategies, such as Just-In-Time (JIT) inventory systems, can help reduce the incidence of overstocking by aligning purchases more closely with actual demand.

Crunching the Numbers: Calculating Obsolete Inventory

The journey to quantify obsolete inventory begins with a two-step process:

Step 1: Clearly demarcate the products constituting your active inventory from those relegated to obsolescence. This foundational step may be executed manually or entrusted to the automation prowess of Excel through the establishment of pertinent date parameters. In industries such as food or pharmaceuticals, products are intrinsically tied to specific dates, which serve as arbiters of their status—active or obsolete. By invoking Excel’s computational prowess, with today’s date as a reference point and the inclusion of start and end dates for each product, you can expediently differentiate between the new and the obsolete. Any product falling outside the defined date parameters is unequivocally marked as ‘obsolete.’

Step 2: Tally the value of your obsolete inventory. Column F, housing the value of your inventory, serves as the bedrock for the computation of obsolete stock value. This mathematical endeavor can be undertaken manually, with each line of obsolete stock highlighted and the division of its value by the total inventory cost. Alternatively, a pivot table can be enlisted to streamline this process.

Quantifying Slow-Moving Inventory

The path to calculating slow-moving inventory commences with the computation of inventory turnover, denoted as Stock Turn. The objective is to determine the inventory turnover for each product, achieved by dividing the inventory value by sales, subsequently multiplied by the relevant period.

Once the formula is applied, rendering the results palpable, you are confronted with the task of prioritization. It is imperative to discern which products merit your initial attention. Notably, products categorized as slow-moving are not inherently obsolete. To further refine this threshold, you possess the latitude to align it with overarching stock turnover, average lead time, reorder points, and safety stock levels.

Indeed, the calibration of this threshold should be meticulously tailored to harmonize with the idiosyncrasies of your business. This endeavor will prove invaluable in delineating a robust strategy for managing excess stock.

Managing slow-moving inventory is an intricate part of supply chain management that requires continuous attention and adaptation. By implementing advanced inventory management systems, refining forecasting techniques, and adopting flexible procurement policies, businesses can significantly mitigate the challenges posed by slow-moving items. Furthermore, innovative approaches to re-marketing or responsibly disposing of slow movers can transform potential liabilities into assets, thereby sustaining business growth and profitability in the competitive market landscape.

In sum, while slow-moving inventory will always be a challenge for inventory managers, it also presents opportunities for improving operational efficiency and strategic decision-making.

Calculating Obsolete and Slow-Moving Inventory (SLOB)

Step 1: Define Active and Obsolete Products

Identify which products are part of your active inventory and which are considered obsolete. This process can be conducted manually or automated in Excel by setting product start and end dates against today’s date. Products within date are labeled ‘New,’ while those beyond these dates are flagged as ‘Obsolete’.

Step 2: Calculate the Value of Obsolete Inventory

In the Excel sheet, include a column that reflects the value of your inventory. To calculate the value of obsolete stock, highlight all entries marked as obsolete and sum their total value. This calculation process can be streamlined using a Pivot table. Tracking the total cost of obsolete stock as a percentage of the total inventory is crucial. Monitoring this key performance indicator (KPI) on a weekly basis is essential, and implementing strategies such as promotions may help reduce the level of obsolete stock (SLOB).

Calculating Slow-Moving Inventory

To determine the slow-moving inventory, start with the Inventory Turnover, which involves dividing the stock value by sales, then multiplying by the number of days. Set thresholds based on your business needs, such as increasing the stock turnover limit to XX days to identify more slow movers, based on an overall turnover of YY days.

Adjust these thresholds according to various product families or business criteria like average lead time, reorder point, and safety stock levels. This helps manage inventory more effectively, catering to different product dynamics.