Description

Supply Chain Management (SCM) is a crucial field in the realm of logistics and business management. It encompasses a multitude of intricate processes aimed at efficiently planning, coordinating, and controlling the flow of products, information, and finances throughout the supply chain. SCM optimizes these activities to maximize operational efficiency, minimize costs, and enhance customer satisfaction.

Key Points:

- SCM is crucial for business efficiency.

- It coordinates the flow of products, information, and finances.

- The goal is to reduce costs and improve customer satisfaction.

- Advanced technologies play a vital role in SCM.

- Process optimization is an ongoing priority.

Demand Forecasting

Demand forecasting is a pivotal element of SCM. It involves using tools and historical data to anticipate future product or service needs. Improved demand forecasting accuracy enables precise planning of production, distribution, and inventory management.

Key Points:

- Demand forecasting relies on historical data.

- It aids in production and distribution planning.

- High accuracy is essential to avoid overstock or stockouts.

- Data analysis tools are widely used.

- Demand forecasting is an ever-evolving science.

Inventory Management

Inventory management is a crucial aspect of SCM. Its aim is to maintain a delicate balance between product availability to meet customer demand and minimizing inventory-related costs. Companies must avoid stockouts while preventing inventory overload.

Key Points:

- Balancing inventory is crucial.

- Storage costs must be minimized.

- Inventory management tools are increasingly sophisticated.

- Effective management ensures product availability.

- Data analysis plays a central role in inventory management.

Key Performance Indicators (KPIs) and Dashboards

Key Performance Indicators (KPIs) and dashboards are crucial elements for assessing and improving SCM operations. They provide an overview of supply chain performance and facilitate informed decision-making.

Key Points:

- KPIs measure SCM performance.

- Dashboards offer a synthesized view of data.

- They aid in decision-making.

- KPI accuracy is essential.

- Real-time data is increasingly used.

Excel Tutorials for Supply Chain

Microsoft Excel remains a ubiquitous tool in the world of SCM. It is used for data analysis, creating forecasting models, managing inventory, and much more.

Key Points:

- Excel is widely used in SCM.

- It enables efficient data analysis and management.

- Excel models are crucial for forecasting.

- Task automation is possible with Excel.

- Excel training is valuable for SCM professionals.

Career in Supply Chain

A career in supply chain offers many exciting opportunities. SCM professionals are essential for ensuring the smooth operation of business operations. From inventory management to logistics planning to data analysis, SCM offers a variety of specialized roles.

Key Points:

- SCM offers a dynamic career path.

- SCM professionals are in high demand.

- Various specializations are possible.

- Expertise in SCM is a valuable asset.

- Continuous education is essential to remain competitive.

Tools & Methodologies in SCM

Supply chain management relies on a multitude of tools and methodologies. From Enterprise Resource Planning (ERP) to Lean and Six Sigma methods, these approaches enhance the efficiency and quality of SCM processes.

Key Points:

- ERPs are essential integrated systems.

- Lean and Six Sigma methodologies focus on efficiency.

- Process automation is increasingly common.

- Continuous optimization is a constant priority.

- Emerging technologies are transforming SCM.

ABC Analysis

ABC analysis is a technique for classifying items based on their relative value. It helps prioritize inventory management by focusing more on high-value items and optimizing their management.

Key Points:

- ABC analysis classifies items by value.

- It prioritizes inventory management.

- A-items have high value.

- C-items have lower value.

- This allows efforts to be concentrated where needed.

Service & Availability Rate

Service and availability rates are essential indicators in SCM. They measure the supply chain’s ability to meet customer demand in a timely manner. High-quality service and consistent availability are key goals.

Key Points:

- Service rates measure customer satisfaction.

- Product availability is crucial.

- Performance indicators monitor these aspects.

- Continuous improvement is necessary.

- Customers demand reliable service.

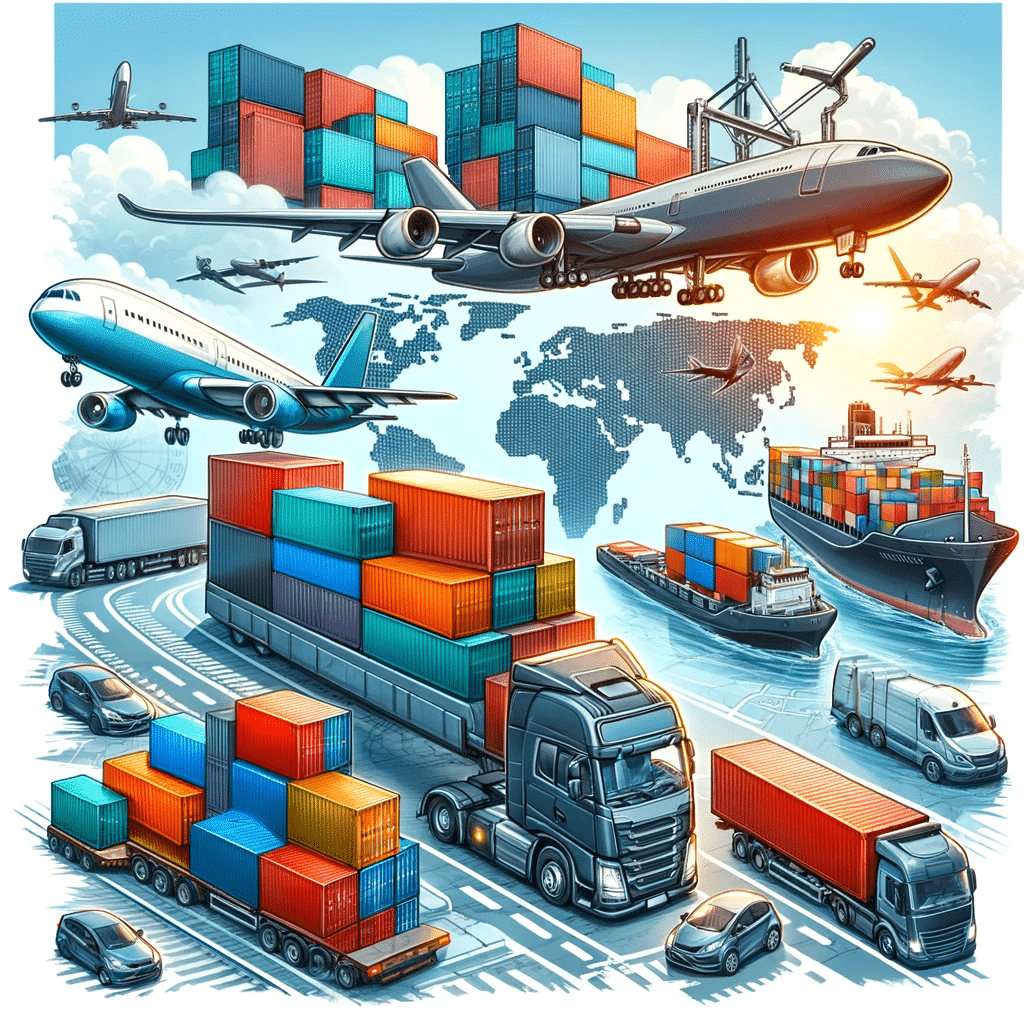

Logistics & Supply Chain Metrics

Logistics is a major field within SCM. It encompasses the management of transportation, storage, and distribution of products. Supply chain metrics evaluate the efficiency of these operations.

Key Points:

- Logistics handles physical distribution.

- Metrics assess logistics performance.

- Route optimization is crucial.

- Parcel tracking is becoming more sophisticated.

- Logistics contributes to customer satisfaction.

Free Webinars on Supply Chain

Free webinars on supply chain offer valuable learning and professional development opportunities. They cover various topics, from inventory management to demand forecasting, allowing SCM professionals to stay updated with best practices.

Key Points:

- Webinars are educational resources.

- They cover various aspects of SCM.

- Continuous learning is essential.

- Experts share their knowledge.

- Webinars are accessible for free online.

Forecasting Models

Forecasting models are essential tools in SCM. They use historical data and variables to predict future demand trends. Accurate models are crucial for effective planning.

Key Points:

- Forecasting models help anticipate demand.

- They rely on historical data.

- Accuracy is crucial to avoid overstock or stockouts.

- SCM professionals develop and improve these models.

- New technologies enhance forecasting accuracy.

Uncertainty in Supply Chain

Uncertainty is a pervasive reality in the supply chain. Factors such as demand fluctuations, delivery delays, and external disruptions can disrupt operations. Managing this uncertainty is an ongoing challenge for SCM professionals.

Key Points:

- Uncertainty is inevitable in SCM.

- Forecasts are based on estimates.

- Delivery delays are common.

- External disruptions are unpredictable.

- Resilience is essential to cope with uncertainty.

Best Practices in Supply Chain

Best practices in supply chain are proven approaches that promote efficiency and quality. They encompass strategies such as demand management, collaboration with suppliers, and cost optimization to improve SCM performance.

Key Points:

- Best practices aim for excellence.

- They optimize processes.

- Demand management is crucial.

- Supplier collaboration strengthens the chain.

- Innovation is a key component of best practices.

Strategies to Boost Supply Chain Career

Boosting a career in supply chain requires strategic planning. SCM professionals can adopt strategies such as continuous learning, specialization, and networking to advance their careers.

Key Points:

- Career planning is essential.

- Continuous learning maintains relevance.

- Specialization creates opportunities.

- Professional networks are valuable.

- Certifications enhance credibility.

This article explores the key aspects of supply chain management, from inventory planning to logistics metrics to demand management. SCM professionals play a crucial role in managing business operations and contributing to customer satisfaction. By following best practices and remaining flexible in the face of uncertainty, they can achieve excellence in this ever-evolving field.