Technoplane Data Activities

Description

Technoplane is helping industrial to improve delevery and shopflood industrial performance, based on data analysis.

https://www.inventorybigdata.com/wp-content/uploads/presentations/PresentationTechnoplaneData.pdf

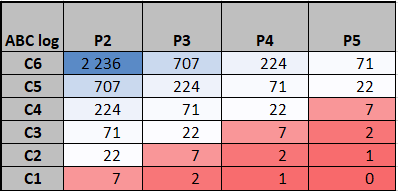

What are data services in inventory management?

Data services in inventory management refer to the collection, storage, and analysis of data related to inventory management. These services can help businesses to more effectively manage their inventory by providing them with real-time data on inventory levels, demand patterns, and other relevant factors.

Some examples of data services in inventory management include:

- Inventory tracking: This involves collecting data on the quantities of each product in stock, as well as the locations of those products within the warehouse or storage facility.

- Demand forecasting: This involves using data on past sales and other relevant factors to predict future demand for a product.

- Safety stock calculation: This involves using data on demand patterns, lead times, and other factors to determine how much safety stock to keep on hand in case of unexpected disruptions in the supply chain.

- Order optimization: This involves using data on demand patterns, lead times, and other factors to determine the most cost-effective way to order and restock inventory.

Data services in inventory management can be provided by software systems or by external service providers, and can be used to support a variety of inventory management strategies, such as just-in-time (JIT) inventory, perpetual inventory, and safety stock inventory.

Why should you call us ?

- Improved efficiency: By analyzing data on a daily basis, a manufacturing company can identify bottlenecks or inefficiencies in their production processes and take steps to address them. This can help to improve overall efficiency and reduce costs.

- Better decision-making: Data analysis tools can provide valuable insights that can inform decision-making at all levels of the organization. For example, data can be used to optimize production schedules, identify new opportunities for growth, or make informed decisions about investments in equipment or processes.

- Quality control: Daily data analysis can help a manufacturing company identify and address quality issues in real-time, reducing the risk of defective products being shipped to customers.

- Improved customer satisfaction: By using data to better understand customer needs and preferences, a manufacturing company can tailor its products and services to better meet those needs, leading to improved customer satisfaction.

Overall, daily data analysis can help a manufacturing company to be more proactive and responsive to changing market conditions, leading to improved performance and competitiveness.

Why KPI are what we are looking first ?

Are you looking to use data to drive better business performance and decision-making? We can help. Our company offers a range of data analysis tools and services designed to help you answer key questions about your business and make informed, data-driven decisions.

With our solutions, you can:

- Understand your key performance indicators (KPIs) and track their performance over time

- Identify and prioritize opportunities for cost reduction and efficiency gains

- Better understand and serve your customers

- Improve the effectiveness of your marketing and sales efforts

- Identify and address potential risks to your business

- Improve the productivity and performance of your employees

- Stay ahead of industry trends and anticipate future developments

Our team of data experts will work with you to understand your specific business needs and goals, and help you implement the right data analysis solutions to drive better results.

Don’t let data be a mystery. Contact us today to learn more about how we can help you use data to drive better business performance.

Why daily foolow-up files are our speciality ?

We understand the importance of using data to drive better performance in manufacturing and supply chain operations. By analyzing key data points on a daily basis, you can identify and address issues in real-time, ensuring that your operations run smoothly and efficiently.

With our data analysis tools and services, you can:

- Monitor production and inventory levels to ensure that you have the right materials and products on hand when you need them

- Identify bottlenecks and inefficiencies in your supply chain and take action to address them

- Track and optimize transportation and logistics to reduce costs and improve delivery times

- Analyze customer data to understand their needs and preferences, and improve your products and services accordingly

By staying on top of your data on a daily basis, you can make informed, data-driven decisions that will help you stay competitive and drive better business results. Contact us today to learn more about how our data analysis solutions can help you improve your manufacturing and supply chain operations.

What should you keep in mind first ?

- What are our key performance indicators (KPIs) and how are they currently performing?

- What are the main drivers of our business performance?

- How can we use data to improve decision-making and strategy?

- What are the current pain points in our operations and how can data help us address them?

- How can we use data to identify and prioritize opportunities for cost reduction and efficiency gains?

- How can we use data to better understand and serve our customers?

- How can we use data to improve the effectiveness of our marketing and sales efforts?

- How can we use data to identify and address potential risks to our business?

- How can we use data to improve the productivity and performance of our employees?

- How can we use data to stay ahead of industry trends and anticipate future developments?

Additional information

| Offer | Cloud Action Plan, Industrial Data Performance, Inventory Big Data |

|---|---|

| Publication |