Description

The Art of Organization: Best Practices for Modern Storekeepers

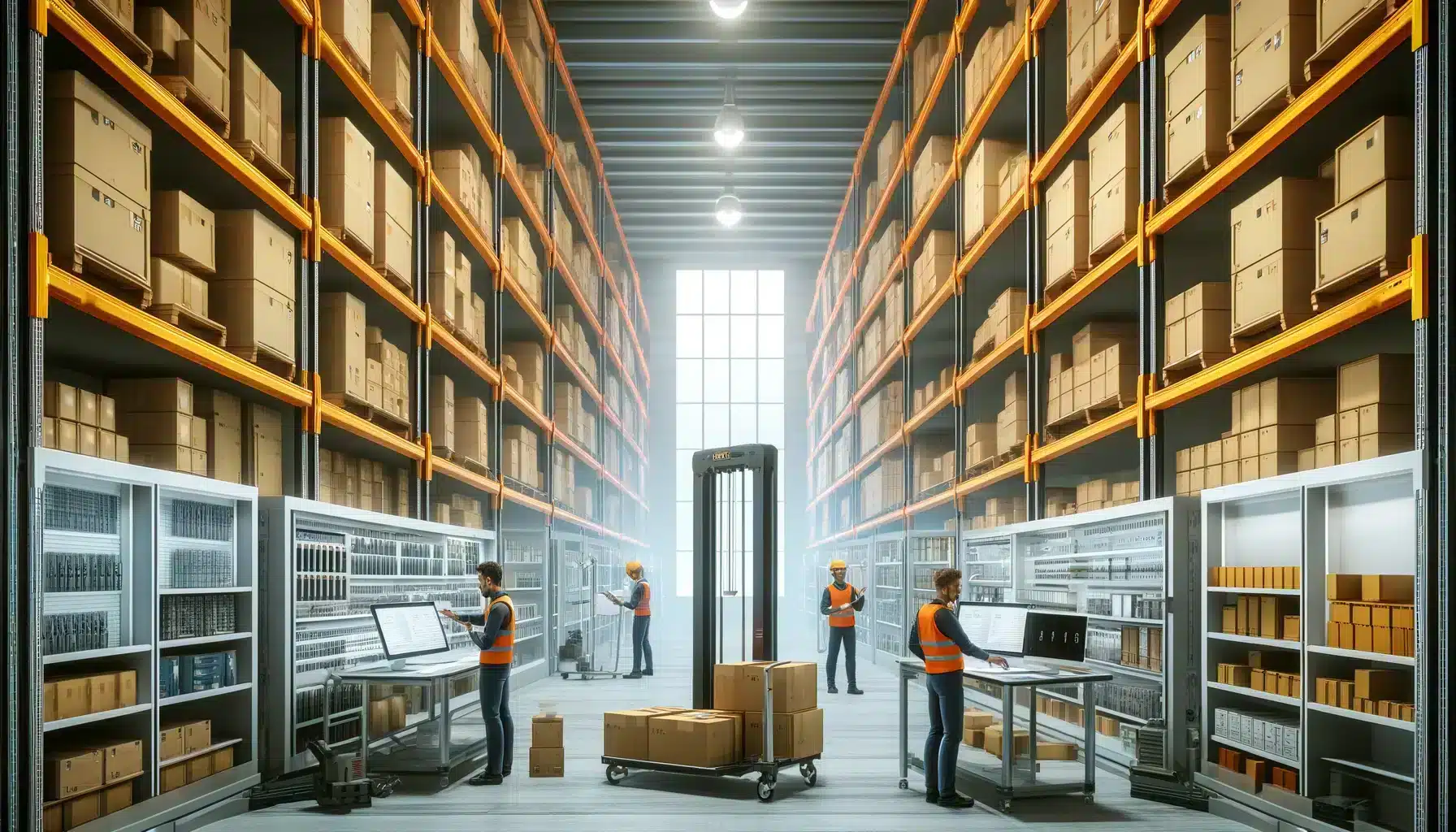

Dive into the organizational techniques that are crucial for efficient storekeeping. This article provides an in-depth look at how modern storekeepers can optimize storage space, categorize inventory effectively, and adopt lean management principles to enhance productivity and reduce waste.

Optimizing Storage Space

Efficient use of space is fundamental in storekeeping. Implementing vertical storage solutions can dramatically increase your storage capacity without expanding the footprint of your warehouse. Use modular shelving and stackable bins to maximize vertical space. Additionally, consider the implementation of mobile shelving systems which can be compacted to eliminate aisles when they are not needed. These adjustments not only save space but also facilitate faster access to items, which can speed up the operation process.

Key Techniques:

- Vertical Storage: Utilize height with modular shelving and stackable bins.

- Mobile Shelving: Compact shelves to eliminate unnecessary aisles, optimizing floor space.

Effective Categorization of Inventory

Proper categorization is key to maintaining an organized inventory. Implement a systematic approach such as the ABC analysis to prioritize items based on their importance and usage rates. This method helps storekeepers focus on managing critical inventory while efficiently organizing less frequently used items. Utilize barcode systems and RFID tags to track inventory accurately and facilitate easy retrieval. This technology not only reduces human error but also speeds up the process of locating and moving stock within the warehouse.

Key Techniques:

- ABC Analysis: Prioritize inventory based on importance and usage.

- Barcode Systems and RFID Tags: Ensure accurate tracking and quick retrieval of inventory.

Implementing Lean Management Principles

Lean management is about eliminating waste and enhancing efficiency. Start by streamlining the inventory process through just-in-time (JIT) inventory systems, which ensure that materials are only ordered and received as needed. This reduces excess stock and minimizes storage costs. Emphasize continuous improvement by regularly reviewing and adjusting workflows to optimize operations. Engage staff in Kaizen events to encourage suggestions for improvements and ensure everyone is focused on increasing operational efficiency.

Key Techniques:

- Just-in-Time (JIT) Systems: Order materials as needed to reduce excess inventory.

- Continuous Improvement: Regularly review and adjust workflows, involve staff in Kaizen events for ongoing enhancements.

Maintaining Orderliness and Streamlining Processes

Organization goes beyond just physical arrangement; it also involves optimizing processes. Develop clear protocols for every task, from receiving new shipments to processing returns. Standard operating procedures (SOPs) ensure that all employees handle tasks consistently and efficiently. Regularly train your team on these procedures to maintain high standards of orderliness. Furthermore, implement a 5S system—Sort, Set in order, Shine, Standardize, and Sustain—to keep the workplace tidy and orderly, which inherently improves productivity and safety.

Key Techniques:

- Standard Operating Procedures (SOPs): Ensure consistency in task handling.

- 5S System: Maintain a tidy and orderly workplace to enhance productivity and safety.

Expert Insights on Industrial Storage

Industry experts emphasize the importance of adaptable storage systems that can grow and change with the business. Investing in scalable and flexible storage solutions can save costs in the long run and accommodate business expansion without the need for significant reinvestment. Experts also recommend regular audits of storage practices and technologies to ensure they remain state-of-the-art and continue to meet the operational demands of the business.

Key Techniques:

- Scalable and Flexible Storage: Invest in adaptable solutions for long-term efficiency.

- Regular Audits: Ensure storage practices and technologies are up-to-date and effective.